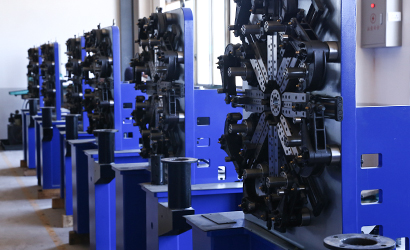

Camless Spring Machine Boosts Efficiency In Modern Production Lines

Industry News-The introduction of the Camless Spring Machine has changed the way manufacturers approach spring production. Unlike traditional mechanical systems, this type of machinery eliminates the need for cams, enabling smoother operations and more adaptable spring designs. Factories that integrate a Camless Spring Machine into their workflow notice immediate improvements in speed and consistency, while also reducing mechanical wear that typically affects conventional systems.

A significant advantage of the Camless Spring Machine is its ability to work seamlessly with a coiling machine, creating a versatile combination that supports a wide range of wire diameters and spring types. This integration allows operators to adjust parameters quickly, producing customized springs without extensive downtime. By reducing the dependence on rigid cam profiles, the Camless Spring Machine can respond more efficiently to design changes, which is particularly valuable in industries requiring frequent adjustments.

Manufacturers report that using a coiling machine alongside a Camless Spring Machine allows for higher throughput while maintaining consistent tension and diameter control. Traditional coiling processes often face limitations when transitioning between different spring sizes or materials. The camless approach mitigates these limitations, offering greater flexibility and fewer interruptions in production. By enabling precise control over wire feeding and coiling, operators can achieve more predictable spring behavior, which reduces waste and ensures that components meet technical specifications reliably.

One of the notable aspects of the Camless Spring Machine is its adaptability. It can accommodate a coiling machine for both light and heavy-duty applications, allowing manufacturers to produce small, intricate springs as well as larger, robust ones. This adaptability is particularly useful in sectors like automotive, electronics, and industrial equipment, where the demand for specialized springs continues to evolve. The elimination of cams also reduces maintenance complexity. Without the need for frequent adjustments to mechanical profiles, maintenance teams can focus on lubrication, calibration, and minor component checks, less production downtime.

The operational efficiency of a Camless Spring Machine extends beyond speed. When paired with a coiling machine, it enables a more streamlined workflow that optimizes labor usage and reduces bottlenecks. Operators can switch between different spring types more easily, shortening the time between production runs. The precise motion control offered by camless technology ensures that the coils are formed accurately, reducing errors and scrap material. Over time, this translates into cost savings and improved resource management for the factory.

Furthermore, the Camless Spring Machine supports advancements in automation. Its programmable nature allows integration with digital monitoring systems, giving manufacturers the ability to track production in real time. When linked with a coiling machine, this digital oversight ensures that deviations from desired specifications are detected immediately, allowing for rapid corrections. This proactive approach helps maintain consistent quality and avoids the accumulation of defective products.

The benefits of the Camless Spring Machine extend to both small-scale and large-scale operations. By combining it with a coiling machine, facilities can meet diverse production requirements while maintaining operational efficiency. The flexibility, precision, and reduced mechanical wear offered by camless technology make it a valuable addition to modern manufacturing lines. Its ability to adapt quickly to changes in design and production demand illustrates a shift in how spring components are manufactured today, offering a practical solution that aligns with evolving industry needs.

The Camless Spring Machine paired with a coiling machine provides manufacturers with enhanced efficiency, flexibility, and quality control. This technology addresses the limitations of traditional spring-forming equipment and presents a path toward more adaptable and reliable production processes. As industries continue to require diverse and precise springs, the adoption of Camless Spring Machine systems represents a thoughtful approach to modern manufacturing challenges.

English

English русский

русский Español

Español 简体中文

简体中文