CNC Spring Coiler Integration Rises In Automated Production Environments

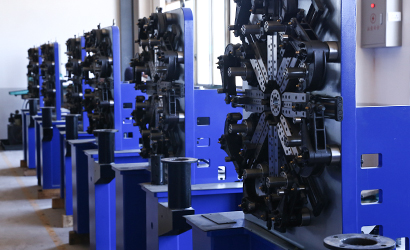

Industry News-The increasing integration of CNC spring coilers in automated production environments has transformed the way industries approach spring manufacturing. As companies seek to improve efficiency and precision, the role of spring forming machines, particularly CNC spring coilers, has become more prominent. These machines offer consistent quality and adaptability that align well with modern production demands.

A CNC spring coiler is a specialized spring forming machine designed to produce springs with high accuracy and repeatability. Unlike traditional manual or semi-automatic methods, CNC spring coilers utilize computer numerical control to bend and coil wire into precise shapes. This control allows manufacturers to maintain tight tolerances, reduce waste, and meet specific design requirements without extensive manual intervention. The adaptability of spring forming machines equipped with CNC spring coilers makes them suitable for various industries, including automotive, electronics, and medical devices.

Automated production environments benefit significantly from the incorporation of CNC spring coilers. These machines can be seamlessly integrated with robotic arms and conveyor systems to streamline the manufacturing process. By automating spring production, companies reduce human error and improve throughput, which is essential for meeting demand in fast-paced markets. The consistent operation of spring forming machines in automated settings ensures that output remains steady, contributing to overall production stability.

The versatility of a spring forming machine that includes a CNC spring coiler is evident in its ability to handle a wide range of wire sizes and materials. Manufacturers can produce compression springs, extension springs, torsion springs, and custom wire forms on a single machine setup. This flexibility reduces the need for multiple machines and simplifies production workflows. Additionally, CNC spring coilers allow quick changes between different spring designs, which is valuable for manufacturers dealing with varied order volumes and customization requirements.

In terms of precision, the CNC spring coiler provides advantages that traditional methods cannot match. The computerized control system accurately guides the wire through the bending and coiling process, resulting in springs that consistently meet design specifications. The spring forming machine’s capability to produce parts with uniform dimensions enhances product reliability, which is crucial in applications where performance and safety are priorities. This precision also lowers the incidence of defects, reducing material waste and rework costs.

Automation combined with CNC spring coiler technology also supports data-driven production management. Many spring forming machines today are equipped with software that monitors performance metrics, allowing operators to track output, machine status, and maintenance needs. This connectivity facilitates proactive maintenance schedules, less downtime and extending the lifespan of the equipment. Moreover, data collected from CNC spring coilers can inform process improvements and quality control measures.

The environmental impact of manufacturing can also be addressed through CNC spring coiler integration. Efficient use of materials and reduction of scrap wire contribute to more sustainable production practices. Since spring forming machines with CNC controls optimize wire usage and less errors, there is less waste generated during manufacturing cycles. This efficiency aligns with broader industry goals to reduce resource consumption and promote environmentally responsible operations.

Companies investing in automated production lines increasingly recognize the value of including CNC spring coilers in their spring forming machines. The ability to combine precision, flexibility, and automation enhances overall manufacturing capabilities. As product designs evolve and demand for customized springs grows, CNC spring coilers offer a solution that meets these challenges without sacrificing efficiency.

The rise of CNC spring coiler integration in automated production environments marks a significant shift in spring manufacturing. Spring forming machines equipped with CNC spring coilers provide consistent quality, operational flexibility, and improved process control. Their use in automation setups helps reduce manual labor, less errors, and support data-driven decision-making. These benefits make CNC spring coilers a valuable component in modern manufacturing, facilitating the production of diverse spring types to meet the needs of various industries.

English

English русский

русский Español

Español 简体中文

简体中文