Camless Spring Machine Enhances Precision For Industrial Components

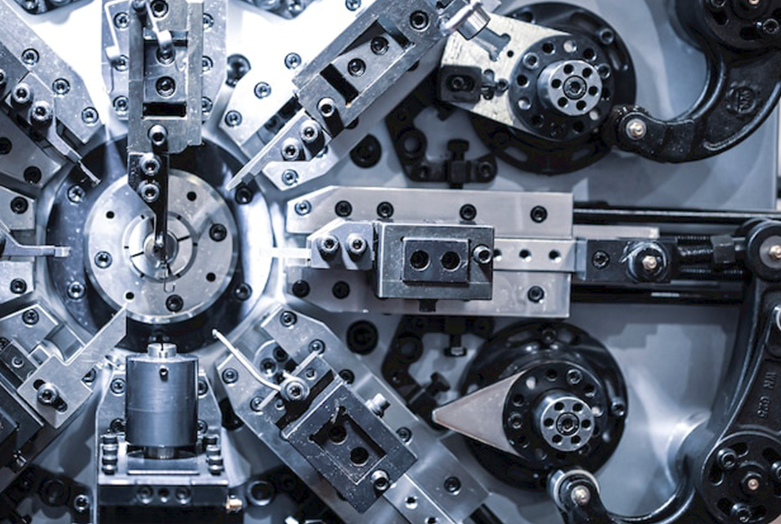

Industry News-In modern manufacturing, the demand for precise spring components has driven the adoption of advanced machinery. The Camless Spring Machine has emerged as a solution that meets these needs without relying on traditional cam systems. Unlike older equipment, this machine offers flexible programming capabilities, allowing operators to produce springs with consistent dimensions and uniform properties. By eliminating mechanical cams, adjustments can be made quickly, reducing downtime and increasing production reliability. The Camless Spring Machine is particularly useful for industries where tolerances are tight and consistency is essential.

Alongside camless systems, the coiling machine continues to play a vital role in spring production. These machines are widely used to shape wire into coils of various sizes and specifications. Modern coiling machines incorporate digital controls, enabling precise adjustments for wire diameter, pitch, and coil length. This level of control ensures that each spring meets design requirements while less material waste. By pairing Camless Spring Machine technology with effective coiling machines, manufacturers can achieve a streamlined workflow that addresses both speed and accuracy.

The benefits of the Camless Spring Machine are not limited to precision alone. Operators appreciate the reduced complexity of maintenance compared to cam-driven systems. Traditional cam mechanisms require frequent inspection and alignment, which can interrupt production. In contrast, the Camless Spring Machine relies on programmable software to guide motion, reducing wear and potential errors. This shift allows maintenance teams to focus on preventive care rather than reactive adjustments. Additionally, the adaptability of this system makes it suitable for producing a variety of spring types, from compression springs to torsion and extension varieties.

In a production line, the coiling machine complements these capabilities. By feeding wire consistently and forming coils according to programmed specifications, the coiling machine ensures that every spring has the intended mechanical properties. Combining a Camless Spring Machine with a high-precision coiling machine offers manufacturers a robust solution for meeting diverse product demands. This combination supports the fabrication of components used in automotive systems, industrial machinery, and consumer products where reliable performance is crucial.

Another notable aspect of the Camless Spring Machine is its efficiency in handling complex designs. Springs with variable pitch, non-standard diameters, or integrated features can be programmed with relative ease. This flexibility reduces the need for multiple setups, cutting advance times while maintaining quality. The software-driven approach allows operators to simulate and adjust production parameters digitally before committing to material, reducing trial-and-error processes. Meanwhile, the coiling machine ensures the wire is formed consistently, translating digital precision into tangible, accurate components.

Manufacturers also recognize the safety advantages associated with Camless Spring Machine technology. By less mechanical linkages and moving parts, the risk of injury during setup or operation is lowered. Operators can monitor production from a distance, adjusting parameters through control panels without direct interaction with high-speed mechanical components. Paired with a coiling machine, this setup provides a controlled and reliable manufacturing environment, maintaining both productivity and workplace safety.

The adoption of Camless Spring Machine and coiling machine technologies is gradually reshaping the spring manufacturing industry. Companies seeking to produce high-precision components efficiently are finding that these tools reduce complexity, enhance flexibility, and maintain consistent quality. As production demands continue to evolve, integrating these machines offers a path toward more adaptable, reliable, and precise manufacturing processes. The combined use of a Camless Spring Machine with a modern coiling machine represents a significant step forward in industrial spring production, meeting the needs of diverse applications with accuracy and efficiency.

English

English русский

русский Español

Español 简体中文

简体中文