Coiling Machine Applications Expand Across Automotive And Electronics

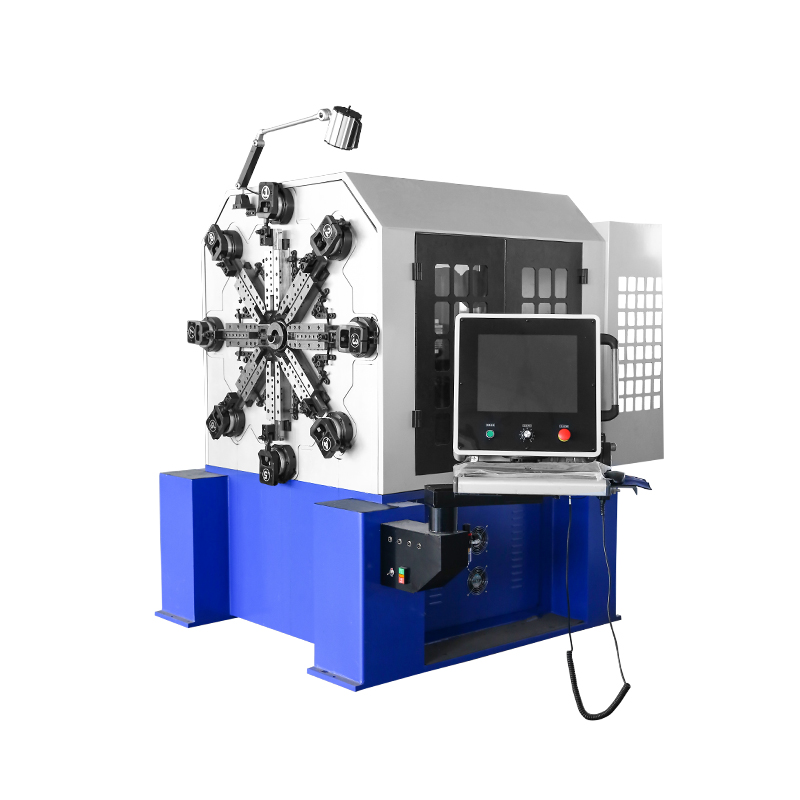

Industry News-In recent years, the use of the coiling machine has grown significantly within the automotive and electronics industries. These machines provide a practical solution for shaping wire and spring components with precision and efficiency. Unlike traditional methods, the Camless Spring Machine offers a streamlined approach to producing complex spring forms without the mechanical limitations of cams, enabling manufacturers to adapt quickly to varying production requirements. The versatility of these machines has made them a staple in workshops that demand flexibility and consistency in output.

One notable area of application is in automotive manufacturing. Springs and coiled components are essential for suspension systems, seat mechanisms, and engine assemblies. A coiling machine allows for consistent production of these components, reducing the chances of irregularities that could affect performance. Meanwhile, a Camless Spring Machine can handle multiple spring types within the same setup, eliminating the need for frequent mechanical adjustments. This flexibility is particularly valuable when manufacturers are dealing with diverse vehicle models or specialized designs, as it less downtime while maintaining product reliability.

Electronics is another sector where the coiling machine plays a critical role. Small, precise springs are used in switches, connectors, and various micro-mechanical assemblies. Using a Camless Spring Machine in this context ensures that delicate components are manufactured with tight tolerances, which is essential for the performance and longevity of electronic devices. The ability to adjust the machine settings without changing cams allows for rapid prototyping and small-batch production, meeting the evolving needs of electronics designers.

Maintenance and operation are key factors for industries adopting coiling machines. Regular calibration, lubrication, and inspection ensure that both the Camless Spring Machine and conventional coiling machines maintain consistent output quality. Operators are increasingly trained to manage machine parameters digitally, which reduces manual intervention and supports more precise production. This approach has contributed to a steady increase in efficiency, especially in settings where high repeatability and small defects are required.

Another important aspect is material versatility. Coiling machines can handle a wide range of metals, from soft copper to hardened steel, providing manufacturers with the ability to produce components for various functions. Similarly, the Camless Spring Machine can accommodate different wire diameters and shapes, making it suitable for specialized automotive springs or miniature electronic components. This adaptability enhances production capabilities without requiring multiple machine types, simplifying workshop layouts and reducing overhead costs.

The adoption of coiling machines has also impacted design creativity. Engineers can experiment with new spring geometries and coil patterns because the Camless Spring Machine eliminates mechanical constraints imposed by cam-based systems. This freedom encourages innovation in both automotive suspension designs and compact electronic assemblies, where space and performance are critical factors. Manufacturers can now meet unique design requirements more efficiently, allowing products to evolve without major retooling.

Overall, the expansion of coiling machine applications across automotive and electronics sectors reflects a shift toward precision, flexibility, and efficiency in component manufacturing. The Camless Spring Machine plays a crucial role in this transition, offering capabilities that support a wide range of production demands while reducing the limitations traditionally associated with cam-driven equipment. Both machines continue to influence how components are designed and produced, demonstrating that adaptability and precision are central to modern manufacturing practices.

English

English русский

русский Español

Español 简体中文

简体中文