Camless Wire Bending Machine Focuses on Precision and Production Efficiency

Industry News-The Camless Wire Bending Machine is frequently discussed in relation to precision control and production efficiency within wire forming environments. As manufacturing processes become more detail-oriented, maintaining consistent quality while supporting efficient operation has become a central concern. Camless systems are increasingly viewed as a practical approach to balancing these priorities in modern wire bending operations.

Growing Attention to Precision in Wire Forming

Precision has become a defining requirement across many wire-based components. Dimensional consistency, repeatable bending angles, and stable forming sequences are essential for ensuring reliable assembly and downstream processing. Traditional mechanical systems can deliver acceptable results in stable production scenarios, yet adjustments may introduce variability when designs change frequently.

Camless wire-bending machines address this challenge by using digitally controlled movements. Each bending action follows programmed instructions, helping maintain consistent forming behavior across repeated production cycles.

Digital Control and Motion Accuracy

The absence of fixed cams allows camless systems to rely on coordinated servo motion. This digital approach enables precise control over feeding, bending, and forming actions. Operators can fine-tune motion paths without altering mechanical structures, supporting consistent output across different production runs.

In wire forming environments where design tolerances are closely monitored, this level of control contributes to improved predictability. Precision is not achieved through mechanical rigidity alone but through controlled and repeatable motion logic.

Efficiency Within Daily Production Operations

Production efficiency extends beyond output speed. It also includes setup procedures, adjustment time, and operational stability. Camless wire-bending machines reduce reliance on manual mechanical changes, which can simplify setup workflows.

When production parameters are adjusted through software, operators can respond more quickly to process requirements. This contributes to smoother transitions between tasks and helps maintain a stable production rhythm throughout the workday.

Consistency Across Production Batches

Batch consistency is another area where camless systems draw attention. Repeated execution of programmed bending sequences helps reduce variation between production batches. This consistency supports quality management efforts and reduces the need for extensive post-production inspection.

For manufacturers serving customers with defined quality expectations, stable batch output can strengthen confidence in wire forming processes and reduce corrective actions.

Practical Benefits for Manufacturing Teams

From an operational perspective, camless wire-bending machines can reduce dependence on specialized mechanical expertise during routine adjustments. Operators can focus on monitoring process behavior and refining parameters rather than managing complex mechanical setups.

This shift supports more streamlined team workflows and allows production staff to allocate attention toward efficiency improvement and quality assurance activities.

Implications for Manufacturing Development

As wire forming continues to integrate digital control principles, camless wire-bending machines illustrate how precision and efficiency can coexist within a single system. Their adoption reflects broader trends toward software-driven manufacturing and controlled automation.

In the long term, such systems are expected to support evolving production standards where consistency, adaptability, and efficient operation are closely interconnected.

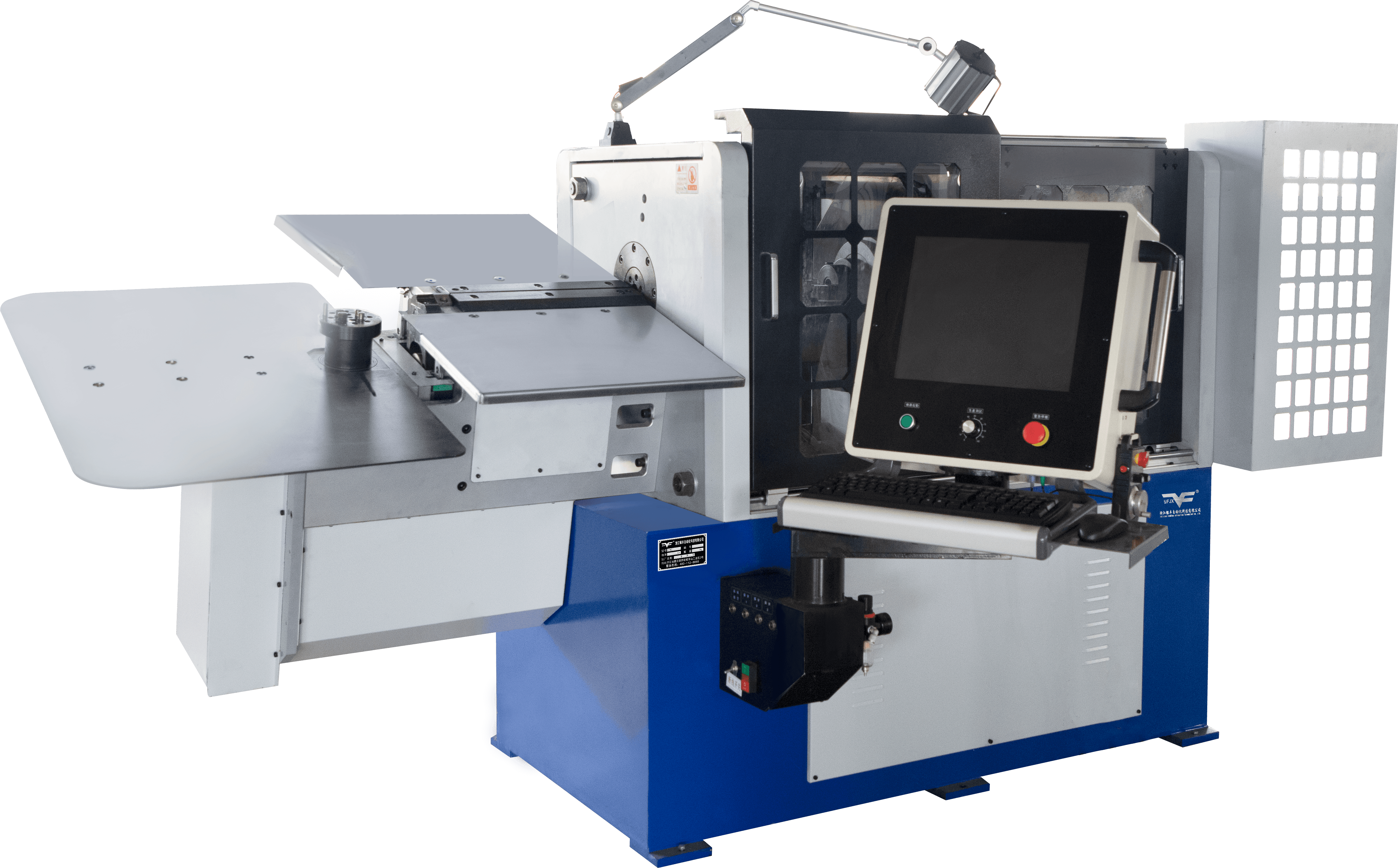

Camless Wire Bending Machine Focuses on Precision and Production Efficiency

The camless wire-bending machine is a core piece of equipment in modern wire forming, renowned for its outstanding precision control and production efficiency. Amid the manufacturing industry’s pursuit of refined production, it perfectly balances stable product quality and high-efficiency operation, becoming a vital choice for enterprises to optimize wire bending processes and enhance production competitiveness.

English

English русский

русский Español

Español 简体中文

简体中文